Checking Out Core Boring Equipment: Crucial Devices for Precision in Geotechnical Investigations

Core exploration equipment plays a necessary duty in geotechnical investigations. These specialized tools make it possible for designers to remove precise samples from varied geological developments. Comprehending the numerous parts, such as drill gears and core bits, is important for effective tasting. As modern technology advances, so too do the methods utilized in core drilling. The ramifications of these growths on safety and accuracy raise essential questions about their application in real-world projects. What challenges stay in maximizing these tools?

Summary of Core Boring Equipment

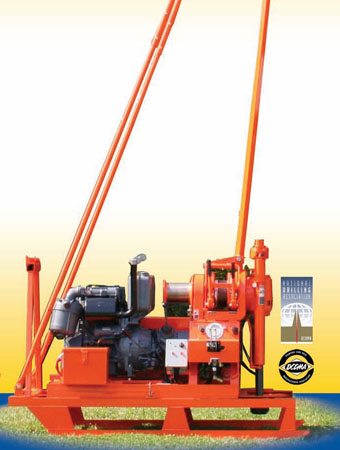

Core drilling devices is crucial for extracting cylindrical samples from different geological developments. This devices usually consists of a drill rig, diamond or carbide-tipped drill bits, and core barrels developed to preserve the tasted material. The drill gear gives the required power and security for the exploration procedure, frequently including hydraulic systems that allow reliable penetration right into acid rock or dirt. Drill little bits are crafted to stand up to extreme stress and abrasion, making certain efficient puncturing various products. Core barrels play a critical role in protecting the honesty and capturing of the samples, permitting precise geological analysis. The tools is often installed on vehicles or trailers for movement, making it possible for accessibility to remote places. Furthermore, innovations in technology have actually led to the growth of mobile and computerized core drilling systems, boosting functional effectiveness and security. In general, core drilling tools is crucial for rock hounds and designers in their quest to understand subsurface conditions.

Kinds Of Core Boring Rigs

Core drilling gears can be found in different types, each developed for geological conditions and certain applications. Rotating exploration rigs, diamond core drills, and wireline core systems represent the primary groups made use of in the sector. Comprehending the characteristics and benefits of each gear kind is crucial for efficient core tasting and geological expedition.

Rotary Boring Rigs

When exploring the various sorts of core exploration gears, rotating drilling gears stand out due to their effectiveness and adaptability in removing geological samples. These rigs utilize a turning drill bit that reduces via rock and soil, making them optimal for a wide variety of applications, consisting of mineral expedition and ecological analyses. Rotary drilling rigs can be classified into different kinds, such as truck-mounted, trailer-mounted, and mobile systems, each created for operational requirements and specific terrains. The rigs frequently employ a boring fluid to cool down the bit and bring pierce cuttings to the surface area, improving the total drilling process. Their robust style and adaptability make rotating boring rigs a recommended choice in geotechnical investigations, assisting in specific and reputable sample collection.

Diamond Core Drills

Diamond core drills stand for a specialized classification of exploration tools developed for high-precision geological sampling. These drills use diamond-impregnated little bits, permitting them to puncture hard rock developments with outstanding effectiveness. The key advantage of diamond core drilling hinges on its capability to produce constant core examples, which are vital for geological evaluation and mineral exploration. Offered in different dimensions and configurations, ruby core drills can be adjusted for various depths and geological problems. They are usually installed on mobile gears, making them versatile for area applications. The precision of diamond core boring not only enhances the high quality of gathered samples but likewise reduces the danger of contamination, consequently making certain trusted information for geotechnical examinations.

Wireline Core Systems

Wireline core systems represent an innovative advancement in core drilling innovation, enabling for reliable retrieval of core examples from substantial midsts. These systems make use of a wireline method that makes it possible for the continual extraction of core examples without the demand to continuously pull the whole drill string from the borehole. This ability considerably minimizes downtime and improves functional efficiency. Wireline core systems are specifically helpful in challenging geological conditions, as they lessen disturbance to the borehole and preserve sample stability. Various kinds of wireline core rigs exist, customized for specific geological settings and task demands. Their versatility and performance make wireline core systems a recommended option in modern geotechnical examinations, making sure exact information collection for design and environmental analyses.

Vital Core Little Bits and Their Applications

Core bits work as vital tools in the area of boring, making it possible for the extraction of round examples from numerous geological formations. These little bits are designed to penetrate different products, consisting of dirt, concrete, and rock, each with certain applications tailored to the geological context. As an example, ruby core little bits are preferred for their longevity and effectiveness when puncturing hard rock, making them suitable for mineral exploration and geotechnical analyses. Conversely, carbide-tipped core bits are generally made use of for softer formations, providing a cost-efficient service for obtaining samples in much less challenging settings. In addition, specialized core bits, such as those equipped for ecological exploration, warranty marginal disruption to the surrounding location, which is vital in contamination assessment projects. The option of core bit straight impacts the quality of the samples accumulated, thus influencing subsequent analyses and decision-making in engineering and environmental evaluations.

Developments in Core Drilling Modern Technology

Recent technologies in core drilling modern technology have considerably boosted the efficiency and performance of geological sampling. Advanced drilling gears now integrate automation and remote surveillance abilities, enabling drivers to gather data in real-time while minimizing human intervention - Core Drilling Equipment. These developments bring about boosted precision and faster completion of drilling projects

In addition, the advancement of high-performance diamond core bits has actually transformed the penetration capabilities of exploration equipment, enabling much deeper and more tough geological developments to be experienced easily. New materials and layers made use of in bit production improve longevity and lower wear, considerably prolonging the life expectancy of core exploration devices.

The combination helpful site of computer-aided style (CAD) software permits for accurate preparation and execution of drilling operations, making it much easier to adapt to differing geological problems. In general, these technological innovations not only streamline the core exploration procedure but also supply geotechnical specialists with indispensable information for informed decision-making.

Safety Considerations in Core Drilling Operations

Security considerations in core drilling operations are critical to guaranteeing the well-being of workers and the honesty of the project. Proper training for drivers is important, as it outfits them with the required skills to deal with devices securely and recognize potential hazards. Individual safety equipment (PPE) such as safety helmets, handwear covers, and eye security need to be worn to alleviate dangers connected with flying particles and heavy equipment.

In addition, normal security audits and threat evaluations must be carried out to determine and address any kind of prospective dangers on-site. Guaranteeing that tools is correctly safeguarded and kept can protect against mishaps related to devices failure. Adequate air flow is additionally essential when drilling in restricted spaces to avoid direct exposure to damaging gases. In addition, establishing clear communication procedures among group participants advertises a more secure working setting. Inevitably, fostering a society of safety is crucial for the successful execution of core exploration operations.

Maintaining and Servicing Core Boring Tools

Servicing and maintaining core exploration devices is essential for making sure peak performance and extending the lifespan of the machinery. Routine inspections need to be performed to determine damage on crucial parts such as drill bits, electric motors, and hydraulic systems - Core Drilling Equipment. Proper cleansing after each usage assists remove particles and prevents rust, which can substantially affect efficiency. Lubrication of relocating parts is vital to decrease rubbing and prevent getting too hot, while additionally enhancing functional performance

Scheduled maintenance routines, consisting page of replacing worn parts and inspecting liquid levels, need to be strictly stuck to. Operators ought to additionally be trained to acknowledge indicators of breakdown, making it possible for prompt repair work and reducing downtime. Maintaining comprehensive service records aids in tracking the equipment's track record and predicting future maintenance needs. On the whole, proactive maintenance not just protects the integrity of core boring equipment however likewise adds to much safer and much more accurate geotechnical investigations.

Case Studies: Successful Applications of Core Drilling in Geotechnical Projects

Core boring has actually shown important in numerous geotechnical projects, particularly in framework advancement and ecological evaluation researches. Study illustrate exactly how this technique helps with the collection of critical subsurface data, educating job planning and execution. These effective applications highlight the versatility and performance of core drilling in resolving intricate geotechnical difficulties.

Infrastructure Advancement Projects

Just how do effective framework growth jobs leverage core exploration to boost geotechnical assessments? Core drilling functions as a necessary device in assessing subsurface problems, allowing engineers to acquire reputable dirt and rock examples. Such analyses are substantial for determining the suitability of websites for numerous facilities, including passages, freeways, and bridges. Significant situation researches highlight how core boring has been made use of in large-scale projects, such as the construction of urban transportation systems. In these circumstances, core examples supplied critical data on dirt make-up and groundwater degrees, assisting in educated decision-making pertaining to foundation style and material choice. The integration of core exploration right into framework advancement not just streamlines project timelines however likewise minimizes risks connected with unexpected subsurface challenges.

Ecological Analysis Researches

While reviewing environmental impacts is essential for sustainable advancement, the application of core exploration in geotechnical tasks has actually confirmed to be very useful. Core drilling makes it possible for the collection of subsurface samples, providing essential information on try this out dirt make-up, groundwater degrees, and pollutant existence. Numerous study highlight its performance in assessing prospective ecological threats prior to construction starts. In a seaside advancement project, core samples determined high degrees of salinity in the dirt, motivating modifications to the initial layout to minimize future erosion threats. Similarly, in urban areas, core exploration has actually contributed in identifying hidden pollutants, making certain that removal efforts are appropriately lined up with job objectives. These applications highlight core exploration's function in cultivating informed decision-making and advertising environmental stewardship.

Regularly Asked Questions

Exactly how Do I Choose the Right Core Boring Devices for My Job?

To select the ideal core boring tools, one need to think about job requirements, soil kinds, deepness needs, and budget plan constraints. Consulting with specialists and assessing tools efficiency rankings can additionally supply beneficial insights for notified decision-making.

What Are the Costs Connected With Core Drilling Equipment Rental?

Prices related to core drilling tools rental normally vary based on devices area, duration, and kind. Usually, prices vary from $100 to $1,000 per day, with added costs for distribution, maintenance, and needed devices.

Can Core Drilling Equipment Be Used in Numerous Dirt Types?

Core exploration tools can be properly used throughout numerous dirt types, consisting of sand, rock, and clay. Its adaptability enables accurate tasting and analysis, making it a beneficial device in varied geotechnical atmospheres and applications.

What Is the Ordinary Life Expectancy of Core Exploration Equipment?

The ordinary life expectancy of core exploration equipment commonly ranges from 10 to two decades, depending upon elements such as maintenance practices, usage regularity, and the conditions in which the devices is operated during drilling projects.

Exactly How Do Environmental Problems Impact Core Exploration Workflow?

Environmental problems substantially impact core boring operations. Aspects such as dirt wetness, temperature level changes, and weather condition patterns can impact devices performance, drilling rate, and the high quality of samples gotten, ultimately affecting project end results and timelines.

Rotary drilling gears, ruby core drills, and wireline core systems stand for the main categories used in the market. When exploring the various kinds of core boring rigs, rotary boring rigs stand out due to their performance and versatility in removing geological examples. The main benefit of diamond core drilling lies in its capacity to generate continual core samples, which are essential for geological analysis and mineral expedition. Wireline core systems stand for a cutting-edge improvement in core boring technology, allowing for reliable access of core examples from considerable depths. Prices linked with core exploration tools rental generally vary based on equipment place, kind, and period.